Key features & benefits

Exceptional high density plasma

The SENTECH SI 500 D ICPECVD System features exceptional plasma properties like high density, low ion energy, and low-pressure plasma deposition of dielectric films and low-damage, low-temperature deposition for passivation layers.

Low-stress ICPECVD

The SENTECH proprietary plasma source technology

The SENTECH Planar Triple Spiral Antenna (PTSA) source is a unique feature of our high-end ICP process systems. The PTSA source generates uniform plasma with high ion density and low ion energy suited for high-quality and low-damage ICPECVD deposition of SiO2, Si3N4, a-Si, SiC, DLC, and doped layers.

Outstanding properties of deposited layers

Low etch rate, high breakdown voltage, low stress, no damage of substrate, and very low interface state density down to deposition temperatures of less than 100 °C allow for outstanding properties of the deposited films.

Dynamic temperature control

Substrate temperature setting and stability during the plasma deposition processes are demanding criteria for high-quality etching. The substrate electrode with dynamic temperature control in combination with Helium (He) backside cooling and substrate backside temperature sensing provides high-quality layers, deposited even at low temperatures.

MIM structure

with ICPECVD SiNx film

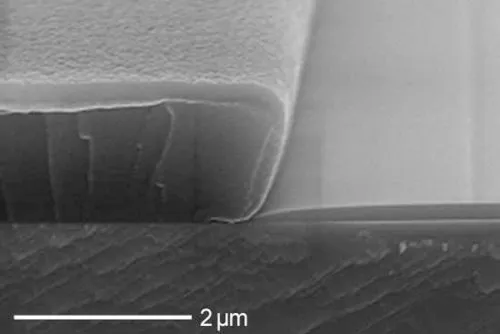

ICPECVD SiNx film on GaSb pixel –

high conformality of the deposition process

Low temperature SiNx –

ICPECVD film for lift-off process

SiO2 stripe deposited over Si edge –

high conformality of ICPECVD

The SENTECH SI 500 D ICPECVD System represents the leading edge for inductively coupled plasma (ICP) processing in both research and industry for plasma-enhanced chemical vapor deposition of dielectric films, a-Si, SiC, and other materials. The system comprises the ICP plasma source PTSA, a dynamic temperature-controlled substrate electrode, and a fully controlled vacuum system. A large variety of substrates from 100 mm wafers up to 200 mm diameter, as well as substrates on carriers can be handled by the flexible load lock built into the SENTECH SI 500 D. The single-wafer vacuum load lock and mechanical clamping guarantees stable conditions and allows for straightforward switching of processes.

Flexibility and modularity

- ICPECVD plasma deposition system

- With vacuum load lock

- Up to 200 mm wafers

- Substrate temperature from RT to 350 °C

- Laser endpoint detection

- Optional substrate bias