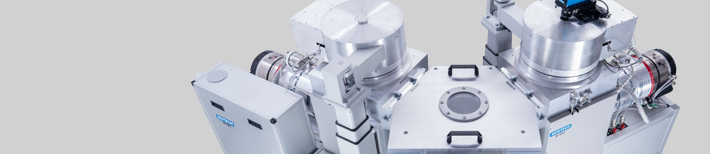

ICP-RIE plasma etcher SI 500

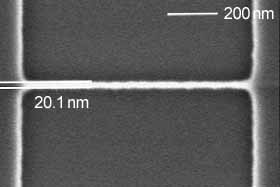

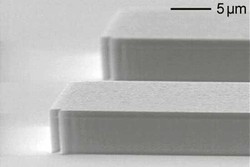

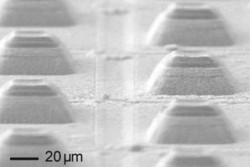

Low damage etching

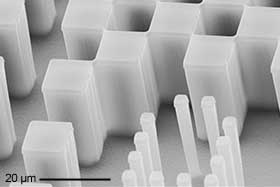

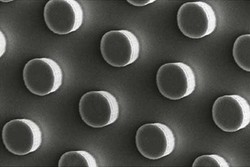

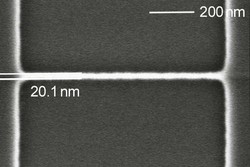

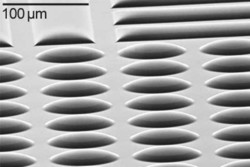

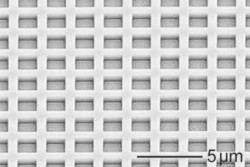

Due to low ion energy and narrow ion energy distribution, low damage etching and nano structuring can be performed with our icp plasma etching tools.

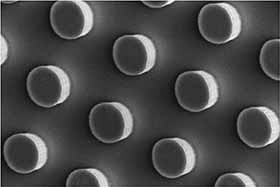

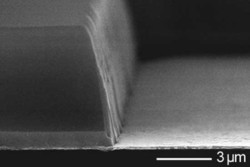

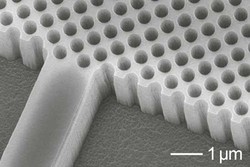

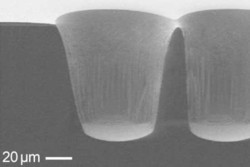

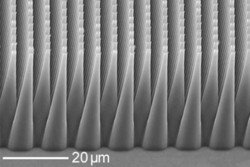

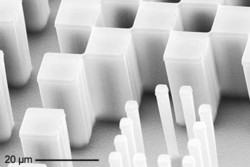

Simple high rate etching

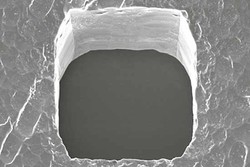

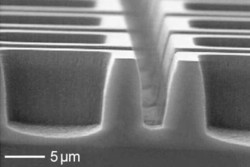

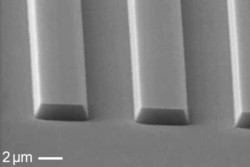

High rate plasma etching of Si for MEMS with high aspect ratio is easily performed either using room temperature alternating processes or cryogenic processes for smooth side walls.

Inhouse ICP plasma source

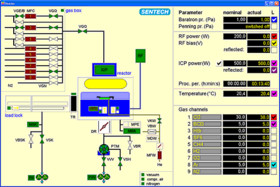

The Planar Triple Spiral Antenna (PTSA) source is a unique feature of SENTECH high end plasma process systems. The PTSA source generates homogeneous plasma with high ion density and low ion energy. It features high coupling efficiency and very good ignition behavior for processing of a large variety of materials and structures.

Dynamic temperature control

Substrate temperature setting and stability during the plasma etching processes are demanding criteria for high quality etching. The ICP substrate electrode with dynamic temperature control in combination with He backside cooling and substrate backside temperature sensing provides excellent process conditions over a wide temperature range from

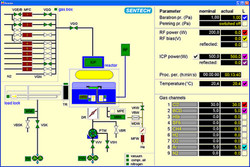

The SI 500 represents the leading edge for inductive coupled plasma (ICP) processing in research and production. It is based on the ICP plasma source PTSA, dynamic temperature controlled substrate electrode, fully controlled vacuum system, advanced SENTECH control software using remote field bus technology, and a very user-friendly general user interface for operating the SI 500. Flexibility and modularity are design characteristics of the SI 500.

A large variety of substrates from wafers up to

The SI 500 ICP plasma etching tool can be configured for processing of a variety of materials, including but not limited to III-V compound semiconductors (GaAs, InP, GaN, InSb), dielectrics, quartz, glass, silicon, silicon compounds (SiC, SiGe), and metals.

SENTECH offers different levels of automation ranging from vacuum cassette loading to one process chamber up to six port cluster with different etch and deposition modules targeted to high flexibility or high throughput. The SI 500 ICP for plasma etching is available as process module on cluster configuration as well.

- ICP plasma etching tool

- With vacuum load lock

- For up to 200 mm wafers

- Substrate temperature from -20 °C to 250 °C

- Optional: -30° to 200°C

- Cryogenic ICP plasma etching system

- With transfer chamber and vacuum load lock

- Substrate temperature from

-150 °C to80 °C (LN2 cooling) - Substrate temperature -10°C to 150°C Bosch process with circulation chiller (optional)

- Automatic switching unit for comfortable change between cryogenic etching and Bosch-process

- RIE plasma etching system

- Smart solution for He backside cooled etching

- Capacitive coupled plasma source,

upgradable to ICP plasma source PTSA 200

- ICP plasma etching system

- With vacuum load lock

- For

300 mm wafers