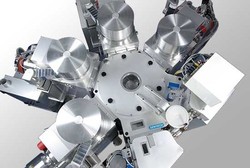

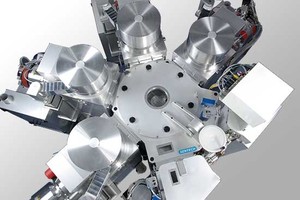

Cluster Configuration for plasma etching & deposition

High throughput

Plasma Etching and deposition modules can be combined with up to two cassette stations for high throughput processing of up to

Research & development

Three to six port transfer chambers are available for clustering ICP plasma etchers, RIE etchers, atomic layer deposition systems, PECVD and ICPECVD deposition tools to meet the requirements of

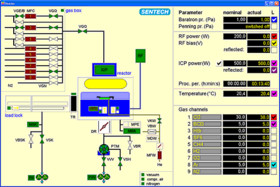

SENTECH cluster tools comprise plasma etching and / or deposition modules, transfer chamber, and vacuum load lock or cassette station. Transfer chambers including handling robot are available with three to six ports. Up to two cassette stations can be used to increase the throughput. The transfer chambers can be equipped with multiple options.

SENTECH cluster tools for

ICP-RIE plasma etching modules can be combined with two cassette stations for high throughput parallel processing of

Modules of ICP-RIE, RIE, PECVD, and ICPECVD can be combined with vacuum load lock and / or cassette station to fulfill the special requirements of